Recently, at parties, 3D printing always comes up when people ask me what I’m working on. I’ve found that people’s reactions to 3D printing vary greatly, and when talking about any new idea, there’s a lot of misconceptions about what 3D printing can and cannot do, and hence, subsequently, what it’s good for.

Given you want to wow your next date (haha), or draw the rapt attention of your fellow party goer, here’s some questions I get commonly asked at parties:

What is 3D printing and how does it work?

3D printers are machines that print physical objects when you give it a digital 3D model. With 3D printing, you can make real, physical objects from digital 3D models. It does this by building the object layer by layer, from the bottom to the top.

Most of the home desktop 3D printers use a technique called Fused Deposition Modeling (FDM), which essentially is a hot glue gun that melts and extrudes plastic through a moving toolhead. There’s other kinds of 3D printers that use different techniques, but the idea is basically the same: we build an object layer by layer by adding to the object–additive manufacturing.

This is in stark contrast to CNC machines, laser cutters, and sculptors, which start with a block of raw material and cut away from it to get the final shape. The advantage of additive manufacturing is that you can make fairly complicated shapes that would be impossible with subtractive manufacturing techniques.

Why the hype recently about 3D printers?

3D printing has been around since the 90’s, but recently certain patents on 3D printing have expired in 2008, allowing hobbyists and researchers to make 3D printers for themselves, on the cheap. There is a project called RepRap, whose goal is to make a 3D printer that can eventually print all its own parts. As a result of the openness of the Reprap project, many hobby-ists learned how to make 3D printers and some went on to found companies to build and sell 3D printers of their own design.

With thegroundswell of activity by 3D printer enthusiasts and designers alike, the media has covered it breathlessly (and on Stephen Colbert). It’s captured the public’s imagination about having Star Trek replicators in the home. It’s both attracted a lot of unfettered optimism along with crushing cynicism. The reality of home desktop 3D printers is somewhere in-between.

What do people print with it?

For commercial and industry printers, there seems to be a few main thrusts. 31.7% of the prints are parts or prototypes for motor vehicles. The second most common are parts and prototypes for consumer products at 18.4%. Then coming in at around 8-10% are all the others, most notably medical and aerospace applications. [source] In reconstructive surgery, some companies are printing exact molds to fit someone’s face, be it a jawbone or ears. In aerospace, some companies are printing strong, but lighter parts for planes, which results in fuel savings.

For the home-desktop printers, it’s spread more evenly across categories. I’ve thought about how to answer this, and the closest I’ve been able to come up with is: People print things that you can imagine, and all the things that you can’t.

At first, many people made upgrade parts for their 3D printers, contributing back design improvements and upgrades to their printers akin to how developers contribute back in open source software. But then people expanded and made functional items, from shower curtain rings, soap dishes, cookie cutters, to shelving brackets. Hardware and gadget enthusiasts also print creative covers for their iphone and their arduino/raspberryPi projects. People make figurines, toys, miniatures, and personalized rings.

But then people make all the things that you couldn’t imagine. One popular piece people print is the heart gears. It’s a function piece of art, where a heart is composed of gears. When the gears turn, the heart deforms until we make two revolutions, which by then, the heart is whole again.

Designers using Shapeways service have printed dresses and bikinis in experimenting of 3D printing and fashion.

Controversially, people are also experimenting with printing gun parts. The lower receiver for the AR-15 has been printed and they have been able to fire off a couple rounds. However, with the groundswell of imagination and attention about 3D printers by the public, national tragedies in gun deaths, and gun control laws under review, this makes for one aspect of 3D printing that has much attention. However, in reality, being able to print fully functional guns is not easy, and will still take years to figure out.

There are different places you can look to see what sort of models people are printing and sharing. Thingiverse is a site run by Makerbot, and are by far the largest collection. My own site, Cubehero is also hosting 3D printed models, but is focused on collaboration and version control. Defcad.org is a place for gun enthusiasts to host their models, since no other hosting site will host them. Shapeways is another place with 3D models to browse, but you can order and sell 3D printed items either you or other people have designed, printed in a variety of materials. There are other sites, but I’ll leave that for a another post.

What kind of materials can you print?

Commercial 3D printers can already print aluminide, sterling silver, glass, ceramics, silicone, sandstone, plastics, metal, cement, wood, paper, In the research circles, people have been able to print with bone, organic tissue, or on an molecular level. Hobbyists have been able to print with chocolate, sugar, and sand.

With home-desktop printers, it’s currently mostly limited to four different kinds of plastics: ABS, PLA, PVA, and Nylon. However, there are also experiments on printing circuits with metal-alloys with low melting points, and conductive plastics.

How much do the materials cost? Is it worth it compared to buying it in the store?

I can only speak to printers that use plastics, which is mostly the home desktop printers. The plastics cost about $40-50 / kg spool. There is water soluble plastic for printing support plastic that costs $90 / kg however. The amount of plastic used per part depends largely on the part, but usually no more than about a $1.

If you can already buy it in the store, it’s almost always not financially worth it to print it yourself. Mass manufacturing and the worldwide shipping supply chain is pretty efficient. However, 3D printing’s strength is in making products that are personalized, one-off things, or things you can’t buy on the shelves anywhere.

Because of this, people often get stuck on thinking about what 3D printers can print that already exist. The real question to ask is, what can they makethat doesn’t yet exist?

What are these different materials and how are they different? How sturdy are the plastic parts?

There are mainly four types of plastics in use by home desktop printers: ABS, PLA, PVA, and Nylon. Each plastic has different properties and are used for different things.

ABS plastic is the most common in use. It’s the same plastic that legos are made out of. The material is pretty strong, and I’ve been able to build shelving brackets with it. It can be tricky to print with ABS since it deforms a little when cooled, but there are ways to combat it.

PLA is a biodegradable plastic made from corn starch that has a lower melting point than ABS and snaps under stress, rather than deform, like ABS. It can be easier to print with than ABS, but it has a higher heat retention, meaning you’d need to cool the plastic as your print it to get it to keep its form.

PVA is a plastic dissolvable in warm water. Because 3D printed objects are built upon the previous layer, it can’t print overhangs lower than 45 degrees. We can print these models by first printing support structure, and then dissolve the structure in water. This can be especially useful in complicated models with overhangs, like the 120-cell.

Nylon is a flexible plastic with a higher melting point, that results in flexible pieces. One application is for iphone cases that are more flexible.

Can you reuse the plastic?

Yes. For ABS and PLA, you can remelt failed prints into filament, and then reuse them again. As of March 2013, there are two projects I’m aware of that melts plastic pellets and extrudes a consistent diameter filament. Filabot is a kickstarter project, though I’ve not heard word on what their status is. Recyclebot is a DIY project that the author has been improving steadily, currently at v2.3. Lyman Extruder is another filament invented by an 83 year old.

I believe there are some experiments with recycling milk jug plastic, but different plastics have different properties, and not all of them are conducive to 3D printing.

Can you print in multiple colors?

For commercial 3D printers, yes, depending on the material. Commercial 3D printers are able to print a type of sandstone or gypsum by using an liquid bonder to bond powder together. During the bonding process, it’s able to inject ink to color the object.

For home desktop 3D printers, the answer is: sort of. The Makerbot Replicator and the Replicator 2x has dual toolheads that you can load different colored plastics. Then as the printer is printing the model, and it needs to switch colors, it uses the other toolhead.

As of this writing (March 2013), however, there has been some experiments on mixing different amounts of different colors to produce a spectrum of colors.

What’s the resolution on an object you can print?

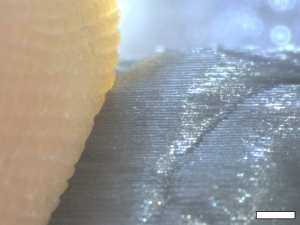

Most desktop 3D printers can easily achieve a layer height of 100 microns. If you run your fingers across it, it feels like a stack of paper. Hobbyists working on the edge of 3D printing hardware have been able to achieve a layer height of 20 microns. If you look at the picture below, that’s the 3D print on the right, and a thumb on the left. However, with FDM printers, it’s a tradeoff between the speed and the resolution of the print.

There are two home-desktop printers that have quite high resolution by using a technique besides Fused Deposition Modeling (FDM). The Form 1 printer uses Stereolithography (SLA), which uses a laser to cure and harden a resin. The PWDR printer project uses a liquid binder to fuse white gypsum powder together.

How much does it cost per print? How long do the prints take?

The answer the both questions depends largely on the model, the resolution of the print, and the printer you’re using. For something about the size of a rubik cube, the cost of the plastic is only $1 or 2, and might take 2 to 4 hours. If one buys ABS pellets and melts them into filament yourself with one of the plastic recyclers mentioned above, then the price drops dramatically. If the resolution of print is low, then it will print much faster.

Lastly, the design of certain printers enables it to make faster prints. The speed of printers as of this writing (March 2013) is tri-modal: one set is grouped at around 150 mm/s, the second at 80 to 100 mm/s, and the last set at 40 to 50 mm/s. The linear speed of the toolhead when it has to move between areas without extruding plastic also helps determine speed of the print. There are some home desktop printers that have a speed of 300 mm/s.

How much is a 3D printer?

Commercial printers are at least $10k. But home desktop printers are about the cost of a computer. Kits that you put together yourself are available for as low as $500. Most assembled printers are around the $1500 range, but there are a few that are around $800, and an outlier, the printrbot Jr. at $400. However, at the high end, they are around $2000 to $2500.

In Conclusion

There’s actually quite a number of other topics not yet covered, such as copyright issues, novel uses and services, and future implications. But armed with the above, you’re well on your ways to being the life of the party! (haha)

Follow me on twitter, if you’d like to learn more.

ok, but how long does it take to make the model in the software?

(I play warhammer 4ok and want to make new models or “conversions”)

making a model in the 3D software like sketchup, solidworks, 123design depends largely on your ability to use. I could create a basic model in 30min with few details and take up to days with more details placed.

Also you can find scanners that can scan the model then place it in 3D software and modify it yourself, possible reducing some of the time. (123Catch iPhone app from Autodesk, or DIY project for Kinnects)

It more deals with your willing ness to commit, learn and drive to learn.